Product Design and Development Companies | Innovative Design and Manufacturing - Manufacturer Profile

Who this is for

- OEMs, fleets, and distributors seeking AU/EU‑standard trailer parts with quick prototyping.

- Engineers and installers needing practical hardware across connectors, brackets, lighting, reflectors, and 12V power.

- Buyers comparing product design and development companies for small‑batch trials and production.

What this page answers

- What does a manufacturer offer under innovative design and manufacturing for trailer systems?

- How do I get a fast prototype for a connector, bracket, or accessory with AU/EU fitment?

- Which processes help move from CAD to testable parts without long lead times?

Real‑world use cases

- Regional compliance: 7‑pin connectors and sockets matched to Australia/Europe wiring standards.

- Mounting stability: steel brackets with e‑coat or black finish for corrosion control around hitches.

- Field power: battery boxes with straps, spacers, and USB 3.0A outputs for RV and marine use.

- Cabin lighting: 12V downlights, rotatable wall lamps, and marine courtesy lights for compact interiors.

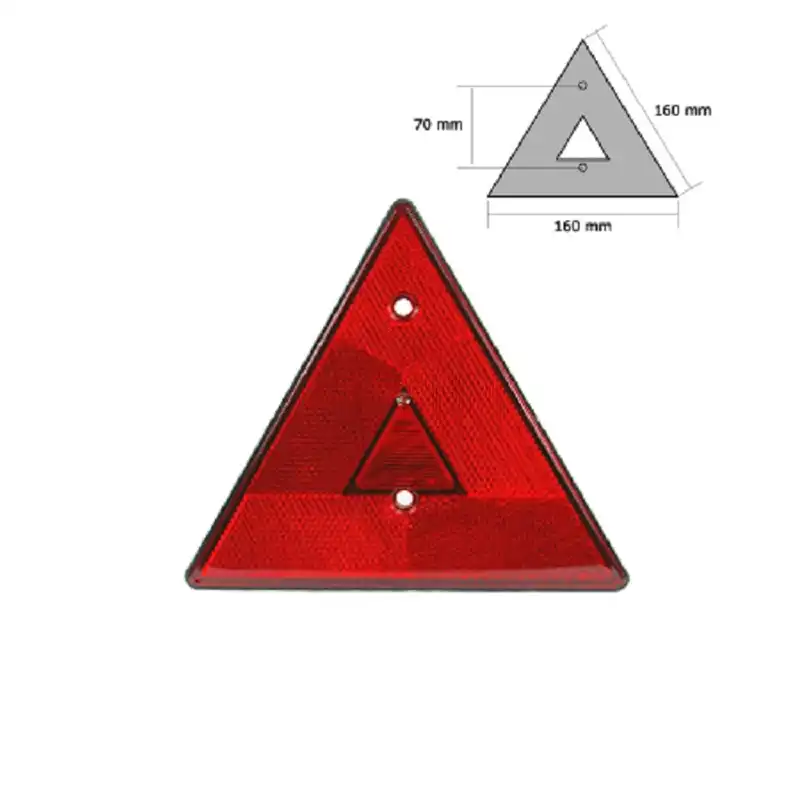

- Visibility and safety: E‑mark reflectors for trailers and boat trailers with consistent mounting patterns.

- Power accessories: dual USB chargers, accessory sockets, voltmeters, and pre‑wired Anderson plugs.

Processes and equipment

- Lathes, milling machines, plastic injection lines, and 3D printers for rapid iteration.

- Prototype‑to‑production pathways supporting small runs before full tooling.

- Material options: coated steels, engineered plastics, and sealed housings tested for vibration and splash.

Outcomes and data points

- Faster design cycles from concept to bench tests using in‑house machining and printing.

- Reduced rework through AU/EU pin‑map alignment and standardized hole patterns.

- Improved serviceability: labeled wiring kits, reinforced brackets, and modular housings.

- Consistent SKUs for trade and fleet inventories to simplify maintenance.

How to choose among product design and development companies

- Verify regional standards (AU/EU) for wiring, brackets, lighting, and reflectors.

- Confirm prototype lead time and available processes (machining, injection, 3D printing).

- Assess material finishes for climate exposure: e‑coat or black steel near hitch and splash zones.

- Request sample fitment: hole spacing, connector geometry, and cable routing.

- Plan scale‑up: small‑batch validation before tooling to reduce cost and delays.

FAQs

- What equipment helps produce a functional prototype quickly? Lathes, mills, injection, and 3D printing shorten iteration.

- How do I ensure my connector meets AU/EU pin standards? Use 7‑pin catalogs and matched sockets with documented pin maps.

- Which bracket finish resists coastal moisture? E‑coated or black finished steel lowers corrosion around the socket area.

- What 12V accessories are common in caravans? Dual USB, accessory sockets, voltmeters, and Anderson plugs.

Why choose us

CUBE CO., LTD. (Taiwan) provides innovative design and manufacturing across AU/EU‑standard trailer connectors, adaptors, brackets, battery boxes, interior lighting, trailer lamps, reflectors, and 12V power accessories, with in‑factory prototyping to accelerate trials and production.